Genesis Medical Plastics’ calendering capability gives medical device manufacturers a dependable source of high-quality film and thin sheet made from their implantable PEEK resin.

Is Calendering a New Technology?

Calendering has been in use for many decades, and like most processing technologies, it has evolved significantly over the years. The process was developed originally as a means of converting rubber into sheets. Decades of process and equipment refinements have made it possible to calender general purpose thermoplastics like PVC and polyethylene into films with progressively higher quality levels and size ranges.

Genesis Medical Plastics has taken calendering to yet another level. Our developments in process controls and equipment technology allow us to calender advanced polymers that exhibit higher process temperature profiles compared to commodity plastics. Most significantly for medical device manufacturers, we can now reliably transform implantable PEEK polymer into consistently high-quality implantable thin sheet and film.

What Is the Film Calendering Process?

In the calendering process, polymers are first melted in the barrel of an extruder. This occurs under controlled pressures and temperatures to prevent degradation of the thermoplastic, a problem that can affect both appearance and physical properties. The molten thermoplastic is then extruded onto one of a series of highly polished metallic rolls in a roll “stack.” The rolls have a gap between them that determines the thickness of the film. As the molten polymer passes between the rolls it gradually cools. At the same time, the pressure of the rolls spreads the material evenly to form a continuous length of high-quality thin film with a uniform width, thickness and surface.

This phase of production requires maintaining process conditions that are specific to each thermoplastic. The metal rolls must be heated and cooled according to the polymer’s thermal stability characteristics to ensure the resulting film has the required appearance, low stress, uniform finish and physical properties.

Why Is PEEK More Challenging to Calender Than Other Plastics?

Most people associate the term “film” with consumer products for packaging and decorative uses. Polyethylene, PVC and polyesters like Mylar are typical examples. These films are made from plastics with relatively low temperature characteristics and are offered in a vast range of widths and thicknesses or “gauges.” They are processed in very high quantities and typically in massive production operations where the emphasis is on high output and low cost.

Advanced polymers such as PEEK pose far different processing challenges. These materials have significantly higher melt temperature profiles that must be precisely monitored and maintained to preserve their properties. Additionally, they have far higher value, and applications are typically more critical. Consequently, quality and consistency are paramount to attaining their optimum benefits in finished products. With implantable PEEK film for medical devices, the challenges are even greater.

Can Genesis Calender Implantable PEEK Film with Consistent Quality?

Calendering implantable PEEK requires a high level of expertise, process control precision and equipment technology to yield consistently high-quality film for use in medical devices. Despite the recognized benefits of PEEK as an implantable material, these production challenges have resulted in an historically limited availability of implantable PEEK film.

Genesis Medical Plastics’ investments in both equipment technology and in dedicated process engineering resources have remedied the historical supply problem. Our development team has a successful record in creating unique approaches to processing advanced polymers. We have capitalized on that experience to design and build production-scale equipment specifically for calendering PEEK film with consistently high quality.

Today our medical polymer conversion capabilities include the ability to calender our clients’ implantable PEEK resins into thin sheet and film produced to their custom specifications. Our rigorous quality procedures ensure consistency in every production run. This capability encompasses production of both standard PEEK film for medical and analytical equipment, and implantable PEEK film, opening the benefits of this proven polymer to many new device applications.

What Sizes of Implantable PEEK Film Can Genesis Produce?

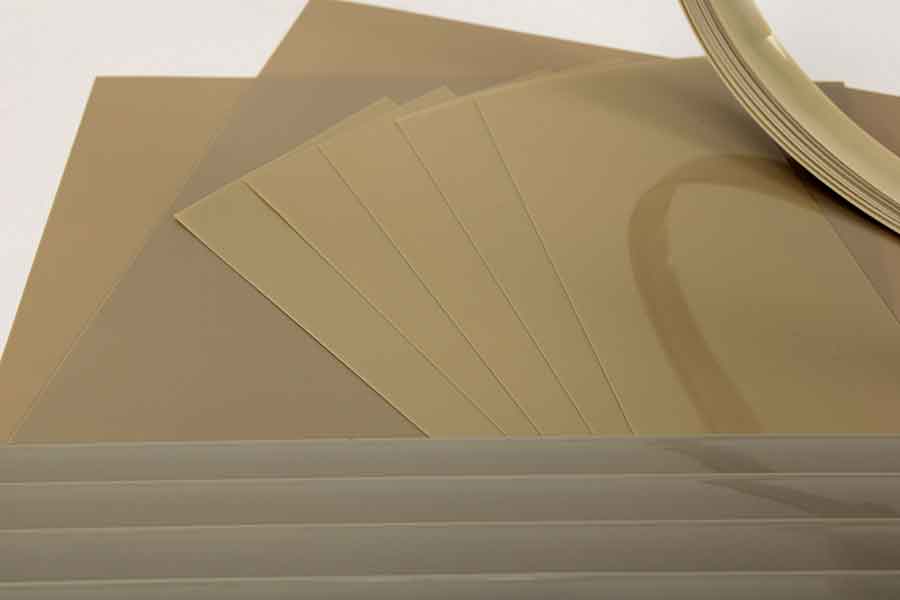

One of the advantages of the calendering process is the ability to produce a wide range of film and thin sheet gauges with a high degree of consistency. While our demonstrated production capability ranges in thicknesses from 0.005-inch (0.127 mm) to 0.040-inch (1.016 mm), we will take on development projects to produce thinner and heavier gauges as customers require.

Our calendering width capability easily satisfies the dimensions required for precision components in bio-electronic and other medical devices. We can provide film in custom-sized flat sheets and in custom-width rolls and strip in the thicknesses our customers specify.

What are Typical Medical Device Applications of Calendered PEEK Film?

With Genesis now offering conversion capabilities for calendering implantable PEEK, the medical and life sciences industries are showing increasing interest in the material for bio-electronics and implantable cardiovascular devices. One example is our work with a device manufacturer who required 0.039-inch PEEK film. The implantable device was being developed for a novel, far less invasive heart procedure.

Because calendered PEEK film can be precision cut, stripped, or stamped, it can be fabricated into intricate components for various bio-electronic and other implantable medical applications such as connectors and components used in defibrillators and pacemakers.

How Did PEEK Evolve into a Medical Grade Polymer?

PEEK has a strong history of reliable performance in many high technology industries where it is used in components that must withstand hot aggressive chemicals, steam, repeated flexing and abrasive wear conditions without failure. It is also chemically inert, has extremely high purity and is not prone to outgassing or leaching at high temperatures or in aggressive fluids.

Leading global producers of the advanced polymer recognized that several of PEEK’s attributes would be beneficial for medical device components and make it an attractive alternative to metals. The essential requirement was to ensure biocompatibility.

Significant product technology investments made it possible to achieve this goal, leading to the availability of implantable PEEK resin on a controlled basis. Genesis converts the resin for our customers into several forms, including stock shapes for machining, injection molded and machined components and calendered film.

What Are the Advantages of Implantable PEEK in Medical Devices?

PEEK has several attributes that make it an attractive material compared to metals and other non-metallics for components in medical devices. Among its benefits:

Biocompatibility and biostability.

Implantable PEEK is inert and exhibits no reaction in contact with body fluids. As a result of its high purity, it can serve as a reliable long-term material for device components such as cardiac implants that are expected to last for many years.

High strength and flexural integrity.

The LIVE procedure requires that materials used for devices maintain their strength and integrity under constant flexing or movement exerted by the heart’s beating. PEEK’s proven resistance to “fatigue” in applications exposed to repeated dynamic forces greater than those encountered in the body make it an attractive option for LIVE.

PEEK film can be fabricated into extremely small precision components that characterize many bio-electronic and other implantable medical devices. Genesis has produced implantable PEEK film in a range of thicknesses down to 0.039 inch (0.99 mm). The film can be made into extremely small components that hold their dimensions during and after fabrication. The availability of different forms of film from Genesis include strip, rolls and custom sheets to accommodate a variety of component designs.