How PEEK is innovating orthopedic procedures?

As people are living longer, the aging population has placed unique and strenuous demands on medical professionals, forcing researchers and medical teams to allocate more resources to conditions that predominantly affect the elderly. Osteoarthritis and damage due to trauma are among common medical issues that plague older people, and their treatment options may require surgical intervention. This is especially the case when knee or hip joints have been damaged or affected by arthritis.

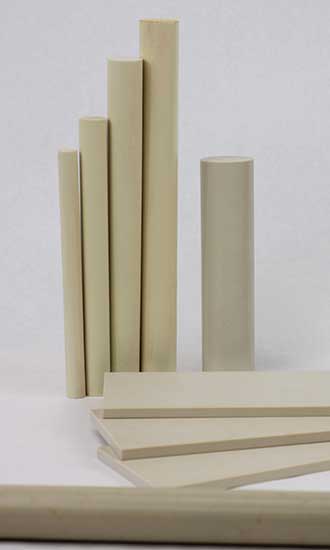

Polymer Components For Orthopedic Procedures

Knee and hip arthroplasty are surgical procedures aimed at replacing the weight-bearing surfaces of the joint to alleviate pain and to restore balance and stability to the joint. Though arthroplasty has undergone some major advancements since its mass adoption, the procedure has been around for more than 50 years, so it is a proven method of reducing pain and improving quality of life.

Knee arthroplasty can either be total or partial. Partial knee arthroplasty is known as unicompartmental arthroplasty and involves replacing one of the knee’s three segments (lateral, medial or patellofemoral). Hip arthroplasty is much like knee arthroplasty, in that it is usually employed to counter trauma to the hip or osteoarthritis. Hip arthroplasty can either be total or hemi (one half).In both cases, the goal of arthroplasty is to remove the problematic parts of the joint, or the entire joint itself, and replace it with an artificial device that closely simulates the movement of a natural knee or hip joint. A knee joint replacement consists of a rounded femoral component, flat tibial component, a patellar “button” and a polyethylene (Ultra-High Molecular Weight Polyethylene; UHMWPE) surface that is attached to the top of the tibial component. The polyethylene surface is either flat or slightly bowled, and its presence ensures that weight is transferred from metal to plastic, instead of metal to metal and importantly acts as an improved bearing and wear interface.

Hip joint replacements include an acetabular component, which is attached to the concave portion of the hip socket, and a femoral head, which is installed on top of the femur. In a hemi hip replacement, only one of the components is replaced. The acetabular component is traditionally made using UHMWPE, again utilized to improve the bearing and wear interface. A femoral stem may be anchored to the remaining femur to provide additional stability.Metals, ceramic and UHMWPE have been the materials of choice for most arthroplasty procedures for many years, but high-performance polymers, such as PEEK, offer a strong alternative. There are significant benefits to PEEK joint replacement components, including:

Metal has long been a favored implant material, partly due to its biocompatibility. PEEK also offers a high degree of biocompatibility and will remain stable and safe after implantation.

2. A similar modulus to bone

Metals are usually inert and safe in the body, but they do not mimic the modulus, or stiffness, of bone. This can lead to stress shielding, and the reduced bone density that comes with it, so it is something to watch for with metal implants. Since PEEK’s modulus is similar to cortical bone, stress shielding is not a concern and the PEEK thereby promotes load sharing between bone and implant, and therefore protects bone density.

3. Noninterference with imaging equipment

PEEK does not produce visual artifacts on CT, MRI or X-ray scans, so it does not interfere with a physician’s ability to evaluate the joint post-operatively to monitor recovery.

PEEK’s physical properties can be altered or augmented with the addition of additives like Carbon Fiber. This versatility means PEEK can be adapted for many orthopedic applications, including those requiring increased strength and modulus.

5. Lighter than metal components

PEEK’s weight advantage over metal is an attribute that is increasingly being recognized for orthopedic components. Lighter weight PEEK components may produce less strain in surrounding tissues and offers easier mobility given the reduced component weight.

Orthopedic procedures are some of the most common among the elderly, and millions of knee and hip joint replacements are performed every year. Many of those patients may benefit from the use of PEEK joint replacement components, as they can serve as a viable alternative to traditional metal and polyethylene joint replacements.